For over four decades, West River Conveyors has been committed to building top-quality conveyor systems and components at competitive prices. Our journey began in 1981 when Joe Street and Jerry Roulett founded West River Machinery Company to manufacture conveyor systems and rebuild mining equipment.

In the early years, we specialized in rebuilding all types of mining equipment, often incorporating conveyor system components into these rebuilds. Recognizing the demand for new, high-quality conveyor solutions, we expanded into manufacturing brand-new belt drives and conveyor components—a move that set us apart in the industry.

By the mid-1980s, we had expanded into the used parts market, particularly in replacement parts for gearboxes and speed reducers. Over the years, we have built an extensive inventory, including:

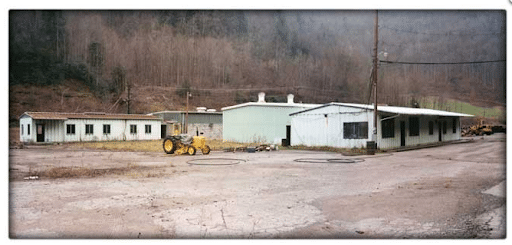

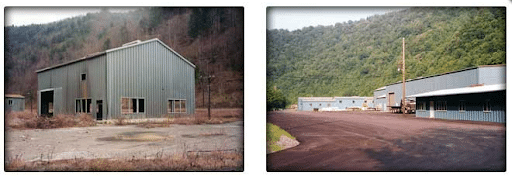

As our business grew, we operated from four separate locations—a setup that was no longer sustainable. In 2000, we made a major move, purchasing 50+ acres to consolidate all operations into a single, modern facility.

Two years of renovations later, we moved into a state-of-the-art facility in 2002. This milestone enabled us to:

Today, West River Conveyors spans 125,000+ square feet of manufacturing and warehousing space, with multiple buildings dedicated to production and inventory.

Ownership remains family-driven, with Joe Street, Pete Savage, and Jessica Savage at the helm.

Despite our growth, our mission remains the same:

West River Conveyors is built on a foundation of reliability and customer commitment, and we look forward to helping you find the right conveyor solutions that meet your needs.

Cost-effective solutions for hauling aggregates like sand and gravel over long distances.

LEARN MORE

Improve mining operations with custom conveyors that are tested for safety and reliability.

LEARN MORE

An online inventory stocked with gearboxes, fluid couplings and other parts ready to be shipped.

LEARN MORE

Avoid unplanned downtime and injuries that can arise from worn out conveyor belts.

LEARN MOREMining conveyors are a marvel of modern engineering. They can withstand the rigors of moving thousands of tons of rock, sand, gravel, and aggregate to their final destination. However, like read more »

We’re Still Here for You – WRC is Fully Operational On Saturday, December 14, an unexpected fire occurred at West River Conveyor's manufacturing facility. While the damage is still being read more »

For any mining operation, conveyor systems are critical, especially when it comes to handling materials in corrosive environments. In Louisiana, one of our longstanding customers operates an underground conveyor system read more »